Plastic injection molding is a rapidly evolving method with a wide range of applications in the manufacturing sector. This technology is one of the most efficient ways to produce high-quality plastic products at low costs. So, what innovations in plastic injection molds have emerged in recent years, and what advantages do they offer to businesses?

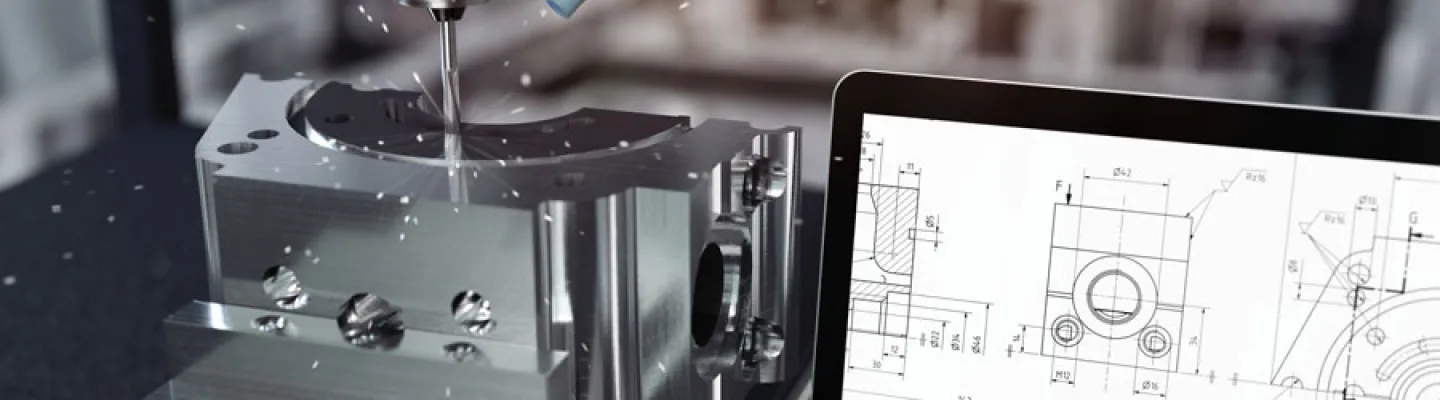

Advanced CNC machines and automation technologies enable molds to be produced faster and with greater precision. Multi-cavity molds, in particular, provide significant advantages in mass production. Thanks to new technologies, it has become possible to increase production speed while minimizing waste rates. Additionally, CAD/CAM software accelerates the mold design process, eliminating error margins and allowing for excellent results.

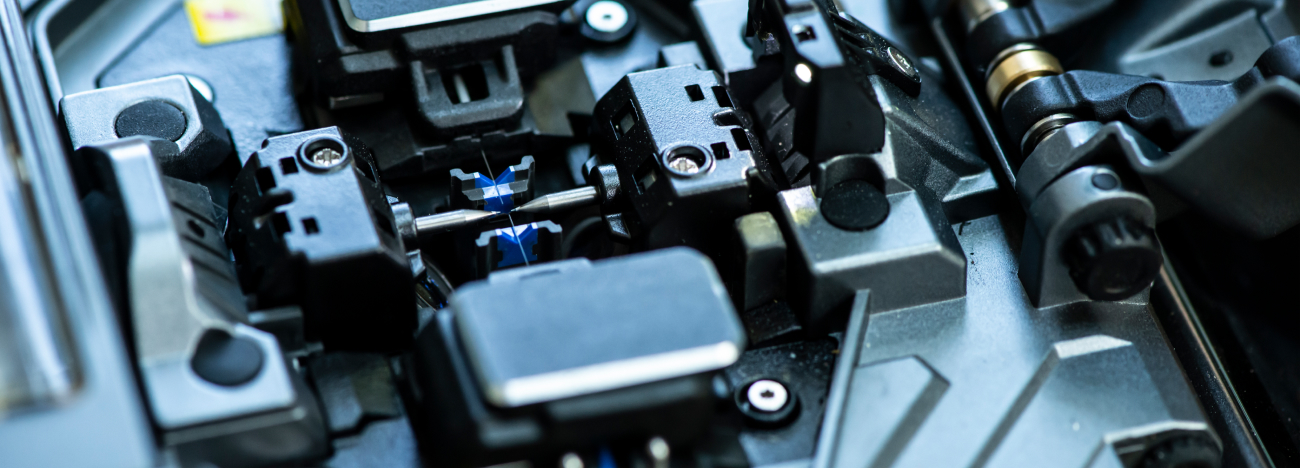

These innovations provide businesses with cost advantages and enhanced competitive power while maximizing product quality. Plastic injection molding has become an indispensable part of efficient production processes, especially in the automotive, electronics, and packaging sectors. With these advancements brought by technology, it is likely that plastic injection will become even more widespread in the future.