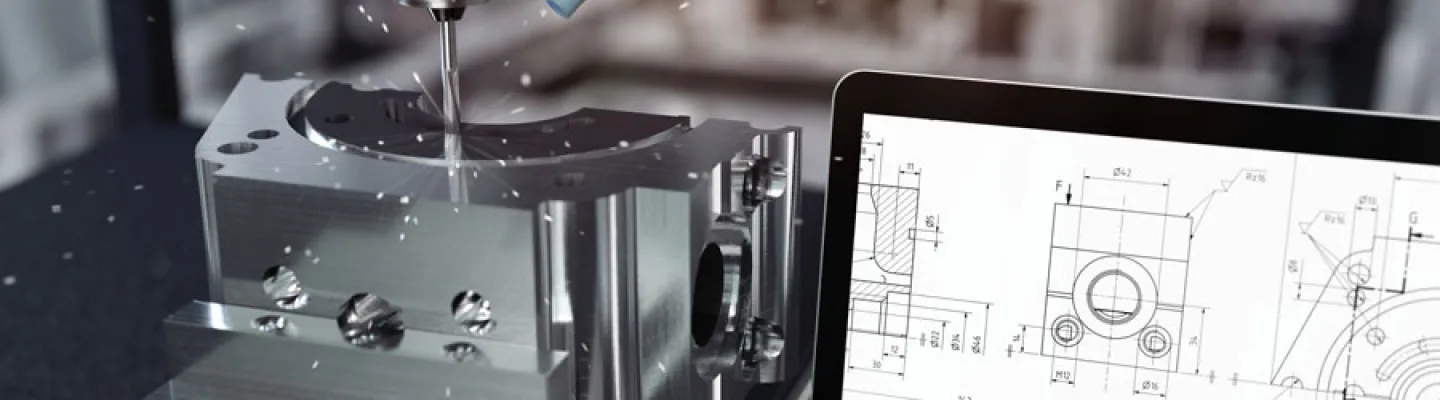

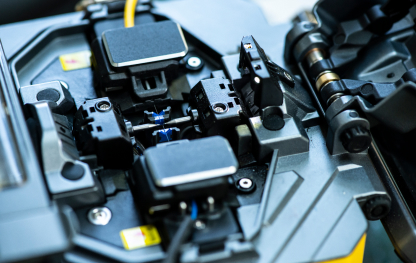

Wire EDM (Electrical Discharge Machining) is a technology widely used in metal machining and mold production processes that require high precision. This method is based on the principle of shaping materials through electrical discharge, making it an extremely precise manufacturing process. So, why is wire EDM technology so important, and what advantages does it offer?

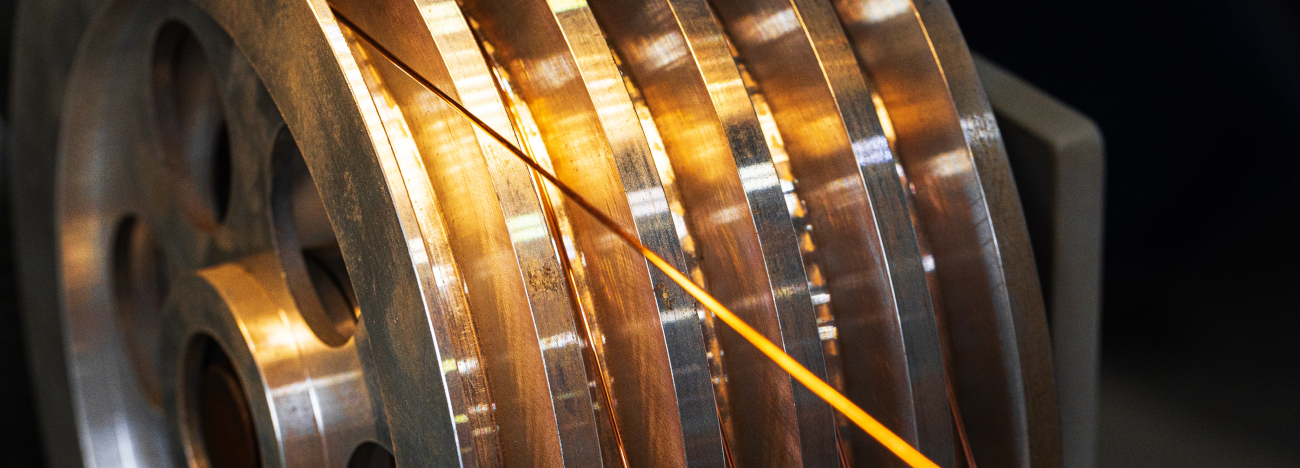

Wire EDM stands out for its ability to process very hard or complex geometries. Especially in sectors that require high precision, such as aerospace, automotive, and medical devices, the results obtained with this technology provide excellent fit and quality. The processing of tough materials, including heat-treated steels, titanium, and tungsten, becomes easier with wire EDM.

Additionally, since no mechanical force is applied to the part during the wire EDM process, there is no deformation of the material. This is a significant advantage for projects requiring high precision and fine craftsmanship. Wire EDM technology, which minimizes the margin of error in manufacturing processes, has become an indispensable part of modern industry.